DOUGH KIBBLER

In the context of food production, a kibbler is responsible for breaking down lumps of dough for further processing – in this case, to be recombined and inserted at the start of the processing line. Point Engineering was asked to design a new kibbler to replace an existing one, which was made of carbon steel and had been in service for considerable time. The size of the lumps of dough returned to the processing line was inconsistent.

-

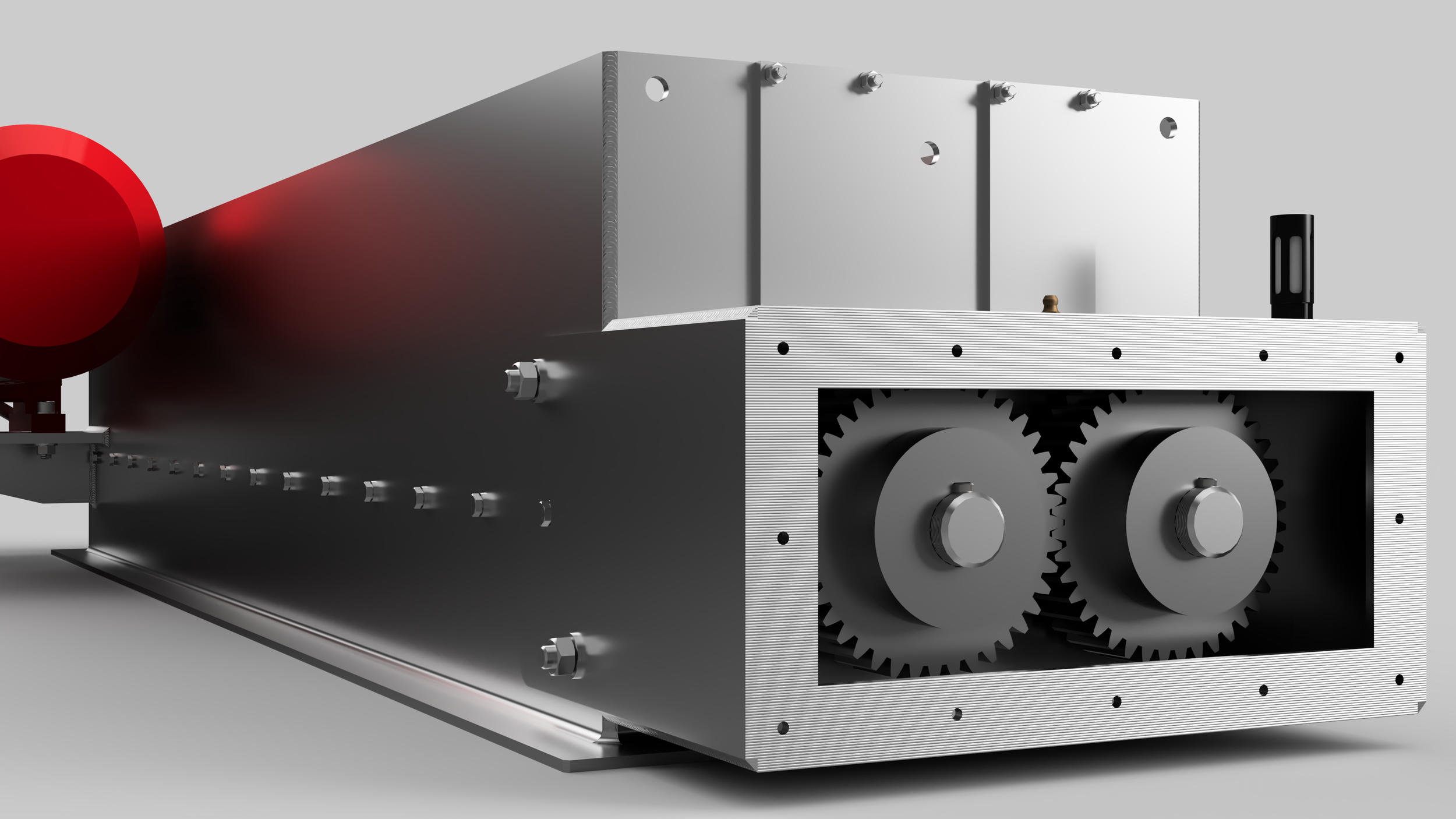

The new kibbler design utilises two oppositely-rotating rotor shafts, with a small clearance between opposing rotors. One of the shafts is driven by an externally mounted electric motor. Timing of the shafts is maintained by a 1:1 spur gear pair mounted to the end of each shaft.

The housing was designed to couple to the existing attachment points, and all major components including the shafts, rotors, bearings, and drive gears are removable to facilitate easy assembly and disassembly. All components were constructed from stainless steel to meet food hygiene requirements, and welds were assigned the appropriate category in accordance with AS/NZS 1554.6.

-

Point Engineering was responsible for the design and drafting of the kibbler. A site-based measure of the existing components was completed to obtain accurate measurements for use in the design.

-

AS/NZS 1554.6